Understanding how to check the Allison 2000 transmission is crucial for maintaining optimal vehicle performance and preventing costly repairs. Regular inspection helps identify potential issues early, avoiding significant breakdowns. This process involves a combination of visual inspections, fluid checks, and operational tests. Proactive maintenance significantly extends the lifespan of this complex transmission system. Ignoring potential problems can lead to premature failure and substantial repair costs. This guide details the steps involved in a comprehensive inspection.

The Allison 2000, a robust automatic transmission known for its durability, still requires periodic assessment. Neglecting regular checks can result in hidden problems escalating into major failures, impacting operational efficiency and leading to unexpected downtime. Early detection of issues, however minor, allows for timely intervention, preventing the accumulation of further damage. The process, while detailed, is manageable with basic mechanical knowledge and the right tools. Proper maintenance practices are essential to maximizing the life of this valuable component.

A thorough inspection involves more than just checking the transmission fluid level. It includes examining the fluid’s condition for discoloration, debris, or unusual smells, all indicative of potential internal problems. Attention should also be paid to external components such as the transmission cooler lines and connections for leaks or damage. Listening for unusual noises during operation, such as whining, grinding, or banging, can alert to internal wear or damage. The steps outlined below provide a systematic approach to a comprehensive evaluation.

Remember, safety is paramount during any vehicle maintenance procedure. Always ensure the vehicle is parked securely on a level surface, the engine is off, and the parking brake is engaged. Appropriate safety equipment, including gloves and eye protection, should be used. Consult the vehicle’s owner’s manual for specific recommendations and warnings related to the Allison 2000 transmission. Following these safety precautions is essential to minimize the risk of injury or damage.

How to Check an Allison 2000 Transmission?

Regularly checking the Allison 2000 transmission is vital for ensuring its longevity and preventing costly repairs. A proactive approach to maintenance significantly reduces the risk of unexpected breakdowns and maximizes operational efficiency. This guide outlines the key steps involved in a thorough transmission inspection. Understanding the system’s functionality and potential failure points is key to effective diagnostics. Remember to always consult your vehicle’s service manual for specific model details and recommendations.

-

Visual Inspection:

Begin by carefully examining the transmission’s exterior for any signs of leaks, damage, or loose connections. Check the transmission fluid pan and cooler lines for any signs of fluid seepage. Pay attention to any unusual sounds emanating from the transmission during operation.

-

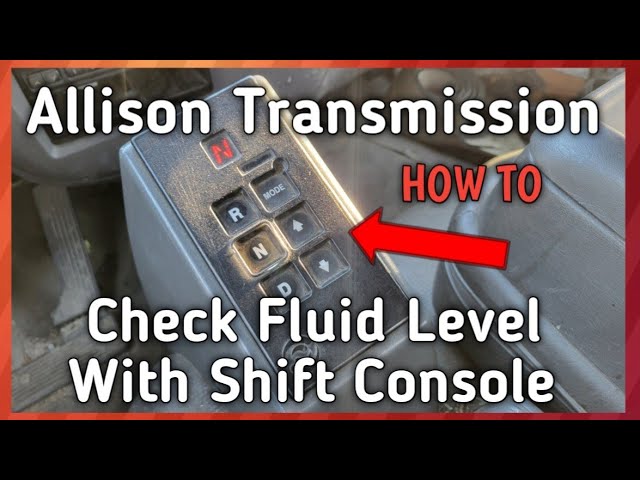

Fluid Level Check:

Locate the transmission dipstick (if equipped) and check the fluid level when the engine is running and at operating temperature. Ensure the level is within the manufacturer’s specified range. Note the fluid’s color and condition; dark or burnt fluid suggests potential problems.

-

Fluid Condition Check:

Inspect the transmission fluid for clarity and smell. Clean fluid should be reddish or amber in color. Dark, burnt, or foul-smelling fluid indicates contamination or potential internal wear. Take a sample and compare it to manufacturer specifications.

-

Operational Test:

Carefully drive the vehicle, paying close attention to the transmission’s shifting behavior. Note any unusual noises, hesitations, slips, or harsh shifts. These symptoms can indicate internal transmission problems requiring professional attention.

-

Temperature Check:

Monitor the transmission fluid temperature using a suitable gauge. Excessively high temperatures can indicate problems with the cooling system or internal transmission issues. Consult the manufacturer’s specifications for acceptable operating temperature ranges.

Tips for Maintaining an Allison 2000 Transmission

Proactive maintenance is key to extending the lifespan of an Allison 2000 transmission. By adhering to a regular maintenance schedule and paying attention to potential warning signs, you can significantly reduce the risk of costly repairs. Proper fluid changes, careful driving habits, and regular inspections are all vital elements of preventative maintenance.

Beyond the basic checks, regular preventative measures contribute significantly to transmission longevity. These practices not only identify potential problems but also mitigate the risk of developing issues altogether. A well-maintained transmission operates more efficiently, providing enhanced performance and fuel economy.

-

Regular Fluid and Filter Changes:

Follow the manufacturer’s recommended schedule for fluid and filter changes. Using the correct type of transmission fluid is essential for optimal performance and longevity.

-

Transmission Cooler Inspection:

Regularly inspect the transmission cooler for leaks, damage, or blockages. A malfunctioning cooler can lead to overheating and premature transmission failure.

-

Avoid Harsh Driving Habits:

Avoid aggressive acceleration, rapid deceleration, and excessive idling. These habits put extra stress on the transmission and can lead to premature wear.

-

Proper Towing Practices:

If towing, adhere to the manufacturer’s guidelines for towing capacity and transmission operation. Overloading the transmission can cause severe damage.

-

Professional Inspections:

Schedule periodic professional inspections by a qualified mechanic to identify potential issues before they become major problems. Preventative maintenance is far less costly than major repairs.

-

Monitor Transmission Temperature:

Keep an eye on the transmission temperature gauge. Sustained high temperatures indicate a problem that needs immediate attention.

-

Address Minor Issues Promptly:

Don’t ignore minor issues like unusual noises or shifting problems. Addressing these early can prevent them from developing into major repairs.

The Allison 2000 transmission, while robust, is a complex piece of machinery. Regular maintenance is not merely a suggestion; it’s a necessary practice to ensure its reliable operation and long-term service. Ignoring warning signs can lead to significant and expensive repairs. By adhering to the recommended maintenance schedule and paying close attention to the transmission’s operation, significant problems can be avoided.

The comprehensive inspection process detailed above provides a strong foundation for preventative maintenance. Proactive attention to the transmission’s health allows for early detection of potential issues, minimizing the likelihood of costly breakdowns. This approach ultimately saves time, money, and frustration in the long run.

Regular maintenance is the cornerstone of maximizing the Allison 2000’s operational lifespan. A diligent approach to preventative care significantly reduces the risk of catastrophic failure, ensuring efficient and reliable operation for years to come. Remember, a small investment in time and resources can yield significant long-term benefits.

Frequently Asked Questions Regarding Allison 2000 Transmission Checks

Understanding the nuances of Allison 2000 transmission maintenance can be challenging. This section addresses frequently asked questions, providing clarity and guidance on effective inspection and maintenance procedures. Remember, consulting a qualified mechanic is always advisable when uncertainty arises.

Q1: How often should I check my Allison 2000 transmission fluid?

The frequency depends on usage and the manufacturer’s recommendations. However, a visual inspection and fluid level check at least every three months, or every 3,000-5,000 miles, is generally recommended. More frequent checks are warranted under heavy-duty usage conditions.

Q2: What does it mean if my Allison 2000 transmission fluid is dark or burnt?

Dark or burnt fluid suggests contamination or internal wear within the transmission. It indicates a potential need for fluid and filter replacement, or possibly more extensive repairs. Immediate attention is advised.

Q3: What should I do if I hear unusual noises coming from my Allison 2000 transmission?

Unusual noises such as whining, grinding, or banging indicate potential internal problems. Immediate professional inspection is crucial to diagnose the issue and prevent further damage.

Q4: Can I check the Allison 2000 transmission fluid myself?

Yes, a fluid level check is generally straightforward. However, checking the fluid’s condition and diagnosing potential problems often requires experience and specialized tools. A qualified mechanic is recommended for a thorough evaluation.

Q5: How important is regular fluid and filter changes for my Allison 2000?

Extremely important. Regular fluid and filter changes are vital for maintaining clean fluid and removing debris, thus preventing internal wear and maximizing transmission lifespan. Adhere to the manufacturer’s recommended intervals.

Q6: What are the signs of an overheating Allison 2000 transmission?

Signs include excessively high transmission fluid temperature, unusual noises (often a high-pitched whine), harsh shifting, and even slipping or complete failure to shift. Immediate action is required to prevent serious damage.

In conclusion, understanding how to effectively check and maintain an Allison 2000 transmission is paramount for ensuring its longevity and optimal vehicle performance. Regular inspections, combined with preventative maintenance practices, contribute significantly to avoiding costly repairs and maximizing the transmission’s operational life. Proactive maintenance is far more economical and efficient than reactive repair.

The information provided here offers a valuable starting point for responsible transmission maintenance. However, it’s crucial to remember that this guide does not substitute for professional advice. For complex issues or uncertainty, always consult a qualified mechanic specializing in Allison transmissions. Regular preventative maintenance remains the most effective strategy for ensuring the continued reliable operation of this critical component.

Ultimately, the comprehensive approach to Allison 2000 transmission inspection outlined here empowers vehicle owners to proactively protect a significant investment. By combining regular checks with diligent preventative measures, the lifespan and reliability of this crucial component can be significantly extended. Remember that proactive maintenance is far more cost-effective and less disruptive than addressing problems after they have developed into major issues.

Youtube Video Reference: