Understanding how to fix a Pilot Precise rolling ball is crucial for maintaining the pen’s smooth writing experience. A malfunctioning ballpoint can lead to skipping, scratching, or inconsistent ink flow. This article details the process of resolving common issues, from simple cleaning to more involved repairs. Addressing these problems can significantly extend the pen’s lifespan and maintain its precision. Proper maintenance prevents frustrating writing interruptions and ensures a consistent, high-quality writing experience. The techniques outlined here are applicable to various Pilot Precise V5 and V7 models.

The Pilot Precise V5 and V7, known for their smooth-flowing ink and fine lines, rely on a small ballpoint within the pen tip to deliver ink effectively. Over time, this ballpoint can become clogged with dried ink, dust, or debris, impairing its function. The precision of the writing instrument is directly dependent on the smooth operation of this tiny ball. Even minor obstructions can significantly impact writing quality. Addressing these minor issues is often a straightforward process involving cleaning or simple adjustments. Regular maintenance can prevent more serious problems from developing.

Another common problem stems from the ink cartridge itself. If the ink flow is inconsistent or insufficient, the cartridge may need replacing. This is a simple solution, often easily accomplished. Pilot Precise refills are readily available. Ensure compatibility with the pen model before purchasing. The correct cartridge ensures optimal ink flow and prevents potential damage to the pen mechanism. Using an incorrect cartridge can lead to leaks or clogged ballpoints.

Finally, damage to the pen tip itself can lead to writing difficulties. Accidental bending or damage to the delicate tip assembly can disrupt the precise alignment of the ballpoint, impacting ink flow. In such cases, repair might require more specialized tools or even replacement of the entire pen tip assembly. Though less common, this type of problem indicates a need for more careful pen handling.

How to fix a Pilot Precise rolling ball?

The Pilot Precise pen, renowned for its fine point and smooth ink flow, occasionally requires attention to maintain optimal writing performance. Addressing issues like clogged ink flow, inconsistent writing, or a damaged ballpoint involves a series of steps that can restore the pen to its original functionality. These steps are straightforward and often require minimal tools. Regular maintenance, following the steps outlined below, will contribute to the long-term usability of the pen. Understanding the underlying mechanism allows for more effective troubleshooting.

-

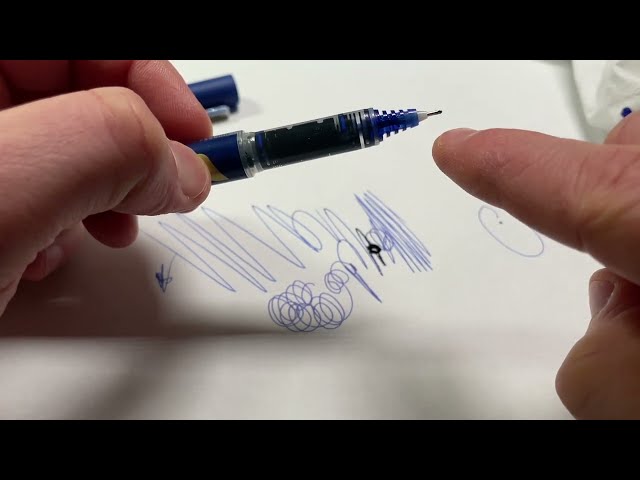

Inspect the Pen Tip:

Carefully examine the pen tip for any visible obstructions such as dried ink, debris, or bent components. Use a magnifying glass if necessary for a closer inspection.

-

Clean the Ballpoint:

If obstructions are found, gently wipe the pen tip with a soft, lint-free cloth. Avoid excessive pressure to prevent damage. A slightly damp cloth may be used, but ensure it is not overly wet to prevent ink from spreading or damaging internal components.

-

Check the Ink Cartridge:

If cleaning does not resolve the issue, examine the ink cartridge for any blockage or air bubbles. If necessary, replace the cartridge with a new one, ensuring compatibility with the pen model.

-

Test the Ink Flow:

After cleaning or replacing the cartridge, test the pen on a piece of paper. Observe the ink flow for smoothness and consistency. If problems persist, proceed to further troubleshooting steps.

-

Assess for Tip Damage:

If the problem continues, inspect the tip for any signs of bending or damage. Bent or damaged tips usually require pen replacement or professional repair.

Tips for Maintaining Optimal Performance

Maintaining the optimal writing experience of a Pilot Precise pen involves consistent care and attention. By employing these preventative measures, users can significantly extend the pen’s life and maintain its consistent writing quality. Regular maintenance prevents the accumulation of debris and dried ink, prolonging the functionality of the ballpoint mechanism. These simple steps can make a noticeable difference in the pen’s performance.

Proactive care avoids more serious problems and ensures a smooth writing experience. The tips below focus on preventative maintenance to keep the pen functioning optimally. Following these steps significantly reduces the need for extensive repairs.

-

Regular Cleaning:

Regularly wipe the pen tip with a soft cloth to remove dust and debris that can accumulate and interfere with ink flow.

-

Proper Storage:

Store the pen in a protective case or pouch to prevent accidental damage and keep the pen tip clean.

-

Avoid Harsh Chemicals:

Avoid exposing the pen to harsh chemicals or extreme temperatures, which can damage the ink cartridge or pen components.

-

Controlled Pressure:

Avoid excessive pressure when writing, which can damage the ballpoint or the pen tip.

-

Ink Cartridge Replacement:

Replace the ink cartridge before it runs completely dry to prevent clogging and maintain consistent ink flow.

-

Avoid Dropping:

Handle the pen carefully to prevent dropping or impacts that can damage the pen’s internal components.

-

Use Appropriate Surfaces:

Writing on rough or abrasive surfaces can damage the pen tip; use smooth paper whenever possible.

The Pilot Precise pens design prioritizes precision and consistency. By understanding the mechanism and following the suggested maintenance, users can consistently enjoy its exceptional writing performance. The pens sophisticated mechanism benefits from regular attention. Regular upkeep contributes to the overall longevity of this high-quality writing tool.

The longevity and continued smooth operation of the Pilot Precise pen depend significantly on the care and attention given to its delicate ballpoint mechanism. By observing the above suggestions and practicing consistent care, users can ensure a satisfying and reliable writing experience for an extended period. Proper maintenance is key to maximizing the performance of this precise instrument.

Ultimately, the goal is to keep the pen’s mechanism clear and lubricated, ensuring consistent ink flow and a smooth, enjoyable writing experience. The cost of maintaining the pen is significantly less than replacing it. Investing time in proper care extends the pens usefulness and minimizes disruptions.

Frequently Asked Questions

Addressing common questions surrounding the maintenance and repair of Pilot Precise pens can clarify any uncertainties and promote better care practices. Understanding the answers to frequently asked questions assists in proactively addressing potential issues and extends the life of this valuable writing tool. The following questions and answers aim to provide comprehensive support.

-

Q: My Pilot Precise pen is skipping. What should I do?

A: First, inspect the pen tip for any obstructions. Clean the tip gently with a soft cloth. If the problem persists, replace the ink cartridge. If the skipping continues after these steps, the ballpoint might be damaged, requiring pen replacement.

-

Q: The ink flow is inconsistent. How can I fix this?

A: Inconsistent ink flow often indicates a clogged ink cartridge or a partially dried-out cartridge. Try replacing the cartridge with a new one. If the problem persists after replacement, inspect the pen tip for any blockages.

-

Q: My pen tip seems damaged. Can it be repaired?

A: Unfortunately, damaged pen tips are usually difficult to repair. The tip assembly is a delicate component. If the tip is significantly bent or broken, the entire pen might need to be replaced.

-

Q: What type of cloth should I use to clean the pen tip?

A: Use a soft, lint-free cloth. Avoid using abrasive materials that could scratch the pen tip. A slightly damp cloth may be helpful for stubborn residue but ensure its not overly wet.

-

Q: How often should I replace the ink cartridge?

A: Replace the ink cartridge before it runs completely dry to prevent clogging and maintain consistent ink flow. The frequency depends on usage but generally, once the ink starts to become noticeably lighter or thinner, it’s time for a replacement.

-

Q: Can I use any type of ink cartridge with my Pilot Precise pen?

A: No, use only Pilot Precise refills designed for your specific pen model. Using incompatible cartridges can lead to leaks or damage to the pens internal components.

Addressing the issues related to the Pilot Precise pen’s functionality requires careful observation and methodical troubleshooting. The underlying principles of maintaining a smooth ink flow and a clean writing surface contribute significantly to the longevity of the pen and provide a consistent, pleasant writing experience. This attention to detail is rewarded with consistent performance.

Regular maintenance is key to ensuring the continued functionality of this valuable writing instrument. The techniques detailed above provide a comprehensive guide for addressing most common problems, enabling users to maintain their pens in optimal condition. Understanding the pen’s inner workings empowers users to resolve minor issues efficiently and effectively.

By applying the provided guidelines and insights, users can significantly improve the longevity and reliable performance of their Pilot Precise pens. The combination of proactive maintenance and effective troubleshooting ensures that these precision writing instruments continue providing a smooth and consistent writing experience for many years. Investing time in these maintenance practices saves both time and money in the long run.

In conclusion, understanding how to fix a Pilot Precise rolling ball involves a combination of careful inspection, cleaning, and, when necessary, replacement of components. Regular maintenance and attention to detail are crucial for ensuring the long-term functionality and consistent writing performance of this precision instrument.

Youtube Video Reference: