Understanding how to repair surfcaster rods is crucial for extending their lifespan and maintaining their performance. A damaged rod can significantly impact casting distance and accuracy, compromising the fishing experience. Proper repair techniques can restore functionality and prevent further damage. This guide details various repair methods, from minor fixes to more extensive repairs. Knowing these techniques can save money and keep your favorite surfcasting equipment in top condition. Ultimately, this knowledge empowers anglers to address rod issues effectively.

Surfcasting rods, subjected to the rigors of saltwater and powerful casts, are prone to damage. Cracks in the blank, broken guides, and damaged reel seats are common issues. The severity of the damage determines the necessary repair approach. Minor repairs might involve simple epoxy applications, while more significant damage may require replacing sections of the blank or entire guides. Careful attention to detail during repairs is essential to ensure structural integrity and maintain the rod’s performance characteristics. Having the right tools and materials greatly simplifies the repair process.

The materials required for rod repair vary depending on the extent of the damage. Epoxy resin and hardener are fundamental for most repairs, providing a strong and durable bond. Guide replacement often requires specialized epoxy designed for bonding metal to composite materials. Additional tools might include sandpaper, a fine-grit file, a heat gun (for shrink tubing), and various sized wrenches. Access to a vise or clamping system can aid in precise repairs, ensuring proper alignment. Having a well-stocked repair kit is beneficial for any angler.

Prevention is key to minimizing the need for repairs. Proper storage, including keeping the rod in a protective case or rod sock, prevents accidental damage. Rinsing the rod with freshwater after each saltwater fishing trip removes corrosive salts that can weaken the blank over time. Regularly inspecting the rod for any signs of damage, such as cracks or loose guides, allows for early intervention and prevents minor problems from escalating into major repairs. These preventative measures significantly extend the lifespan of a surfcasting rod.

How to Repair a Surfcaster Rod?

Effective surfcaster rod repair necessitates a methodical approach, starting with a thorough assessment of the damage. Identifying the type and severity of the damage informs the appropriate repair strategy. This might range from a simple guide replacement to a more complex blank repair, requiring specific tools and materials. Accurate diagnosis is crucial to ensure a successful and lasting repair. Before commencing any repairs, gather all necessary tools and materials to streamline the process and avoid interruptions.

-

Assess the Damage:

Carefully examine the rod to pinpoint the location and extent of the damage. Note the type of damage (e.g., cracked blank, broken guide, damaged reel seat). This assessment will determine the required repair method and necessary materials.

-

Gather Materials and Tools:

Assemble the required materials, including epoxy resin and hardener, sandpaper, suitable guide, new shrink tubing (if replacing a guide), a heat gun, and appropriate wrenches or pliers. Having all necessary items readily available streamlines the repair process.

-

Prepare the Surface:

Clean the damaged area thoroughly, removing any dirt, debris, or old adhesive. Lightly sand the area to create a rough surface that promotes better adhesion of the epoxy. This step is crucial for a strong and durable bond.

-

Apply Epoxy:

Mix the epoxy resin and hardener according to the manufacturer’s instructions. Apply a generous amount of epoxy to the damaged area, ensuring complete coverage. For guide replacements, carefully position the new guide and secure it with epoxy. Allow ample curing time as specified by the epoxy manufacturer.

-

Cure and Finish:

Allow the epoxy to cure completely, avoiding any stress or pressure on the repair area during the curing process. Once cured, carefully sand away any excess epoxy, ensuring a smooth finish. This step maintains the rod’s aesthetic appearance and prevents snags.

Tips for Successful Surfcaster Rod Repair

Successful repair requires careful attention to detail and the use of appropriate techniques. The correct epoxy is paramount for effective bonding and long-lasting repairs. Precision in application and curing is critical for maintaining the structural integrity of the rod and restoring its original performance characteristics. Utilizing the proper tools enhances accuracy and simplifies the process.

Following the manufacturer’s instructions for any materials used, particularly epoxy, is crucial. Different epoxies have varying cure times and application methods. Understanding these specifics ensures the repair’s durability and effectiveness. Improper application can lead to a weakened repair prone to failure under stress.

-

Use High-Quality Epoxy:

Invest in a high-quality epoxy designed for rod repair to ensure a strong and durable bond. The epoxys strength directly impacts the repair’s longevity.

-

Clean the Repair Area Thoroughly:

Thorough cleaning of the damaged area before applying epoxy ensures proper adhesion. Any residue can compromise the bonds strength.

-

Allow Sufficient Curing Time:

Give the epoxy ample time to cure completely before handling or using the rod. Premature use can weaken or damage the repair.

-

Use the Right Tools:

Appropriate tools, such as a vise or clamps, ensure precise alignment during repairs. Improper alignment can affect the rod’s casting performance.

-

Sand Smoothly:

Careful sanding of excess epoxy creates a smooth finish, preventing snags during use.

-

Consider Professional Repair:

For extensive damage or complex repairs, consider seeking professional assistance from a rod repair specialist.

Regular maintenance plays a crucial role in preventing the need for repairs. Proper storage and cleaning after each use protect the rod from damage and extend its lifespan. Following these preventative measures minimizes the likelihood of requiring major repairs. Understanding the signs of potential damage enables early intervention and prevents minor issues from becoming significant problems.

The choice between attempting a repair oneself or seeking professional assistance depends on the severity of the damage and one’s skill level. Minor repairs, such as replacing a guide, are often manageable for someone with basic repair skills. However, more extensive damage, such as a cracked blank, may necessitate professional assistance to ensure a successful and lasting repair.

The overall goal of any surfcaster rod repair is to restore the rod’s functionality and structural integrity. Successful repair requires a combination of proper assessment, appropriate materials and tools, meticulous application, and adequate curing time. By following these guidelines, anglers can extend the life of their valuable fishing equipment.

Frequently Asked Questions about Surfcaster Rod Repair

Addressing common queries concerning surfcaster rod repair clarifies uncertainties and empowers anglers to make informed decisions regarding maintenance and repair strategies. This section addresses typical questions related to repair materials, procedures, and when professional assistance may be needed.

Q1: What type of epoxy is best for repairing a surfcaster rod?

A high-quality two-part epoxy designed for rod building or repair is recommended. Look for epoxies with high tensile strength and good UV resistance for outdoor durability.

Q2: How long does epoxy need to cure before using the rod?

Allow at least 24 hours for the epoxy to fully cure. Refer to the manufacturer’s instructions for the specific epoxy used, as cure times may vary.

Q3: Can I repair a cracked rod blank myself?

Minor cracks might be repairable with epoxy, but significant cracks may require professional repair or replacement of the damaged section. Consider the extent of the damage and your skill level.

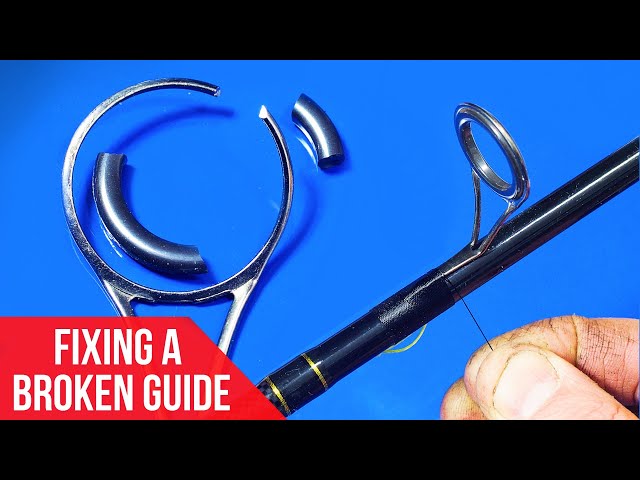

Q4: How do I replace a broken guide?

Remove the broken guide, clean the area, and apply epoxy to the new guide before carefully attaching it to the blank. Use heat-shrink tubing to secure the guide in place, ensuring proper alignment and a snug fit.

Q5: When should I seek professional rod repair?

Seek professional assistance for significant damage, complex repairs (like a severely cracked blank), or if you lack confidence in your repair skills. Professional repair ensures a properly functioning rod.

Q6: How can I prevent surfcaster rod damage?

Rinse the rod with freshwater after each use, store it in a protective case, and inspect it regularly for any signs of wear or damage. These preventative measures extend the rods lifespan.

Successful surfcaster rod repair hinges on a careful assessment of the damage and the subsequent selection of appropriate repair techniques. The availability of various repair methods allows for the restoration of functionality across a spectrum of damage severity. Each repair, whether minor or extensive, necessitates meticulous attention to detail throughout the process.

Choosing the right materials is equally crucial; using high-quality epoxy specifically designed for rod repair ensures a robust and lasting fix. The proper application of this epoxy, combined with sufficient curing time, is essential to maintain the rods structural integrity. Neglecting these aspects can compromise the repair and potentially lead to further damage.

Ultimately, mastering the art of surfcaster rod repair empowers anglers to maintain their equipment, extend its lifespan, and optimize its performance. This proficiency translates directly into a more enjoyable and successful fishing experience, preserving a valuable investment. By implementing preventative measures and learning proper repair techniques, anglers can effectively manage and mitigate potential damage to their surfcasting rods.

Therefore, understanding how to repair surfcaster rods is a valuable skill for any serious angler, offering cost savings, improved equipment longevity, and ultimately, a more fulfilling fishing experience.

Youtube Video Reference: